Hot Products

Introduction to the Most Important Facilities in Aluminum Ashes Facilities

E-mail: market@hxjq.comHongxing Mining Machinery Co., Ltd is devoted to the research and development on the producing technology and equipment of the aluminum ashes, producing the best aluminum ashes product line in the market of our company. The aluminum ashes dealt by the aluminum ash concentrating machine as well as the cool aluminum ash without separating can be classified by the choosing aluminum ash ball mill, mixing mill, and other separating machines, until the aluminum ash become the aluminum ingot. Aiming at protecting the environment, the closed ores ash production line is be designed.

The aluminum ash concentrating machine is mainly applied to the recycle of aluminum ash, aluminum dross, Pb ash, Pb dross and other non-ferrous metal.

The advantages of aluminum ash concentrating machine:

1.Small investigation and high handling capacity. A 40,000- yuan facility can handle 1.5 to 1.8 tons of products.

2.Low cost.

3.High recycling. The recycling rate of the aluminum ash equipment can reach 98%.

4.Little pollution. The traditional methods of selecting aluminum ash mainly are to use the stone or the aluminum ash ball mill to separate, which needs high working strength and large number of workers, and does harm to the environment. This equipment uses the outlay dust control to reach the purpose of protecting the environment.

5.Simple producing process. This kind of aluminum ash equipment can put the jaw materials into the machine, through whose handling the aluminum ash gets into the reelecting equipment to separate the aluminum ash from the aluminum particles. The whole process can work atomically without people's handling, which can save time and labor.

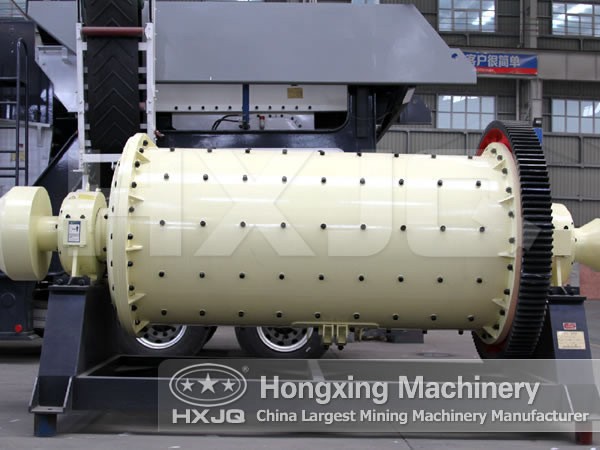

Selecting Aluminum Ash Ball Mill

Henan Hongxing Mining Machinery Co. Ltd. Can provide various sizes and types of selecting aluminum ash equipment ofφ900-φ5000 to the metallurgy and chemistry industry. This equipment has the advantages of:

1.The rolling bearings are used to replace the sliding bearings, which can save the electricity of over 30%.

2.The cylinder of the ball mill uses the automatic welding , the ultrasonic testing, integrallyannealed, large professional machine with card processing and other measures to ensure the precision and quality of the product.

3.The ball mill use the rare earth materials and new type structural scaleboard to adjust the rotating speed of the machine, optimize the designing of the gears and thus prolong the life of the ball mill.

4.The selecting aluminum ash ball mill will be installed and debugged before sold, which can make the field installation easier.