Flotation plant

Working capacity: 0.18-7m3/min

Size of raw material: 2mm-10mm

Raw material: feldspar, calcite, talc, fluorite, rare earth, ceramic, bauxite, gold ore, copper ore, silver ore , manganese ore, lead-zinc ore, nickel ore, phosphate ore, etc

Technical advantage: high working efficiency, low energy consumption, strong working capacity, reasonable price Get price list

you can click the button and contact us.

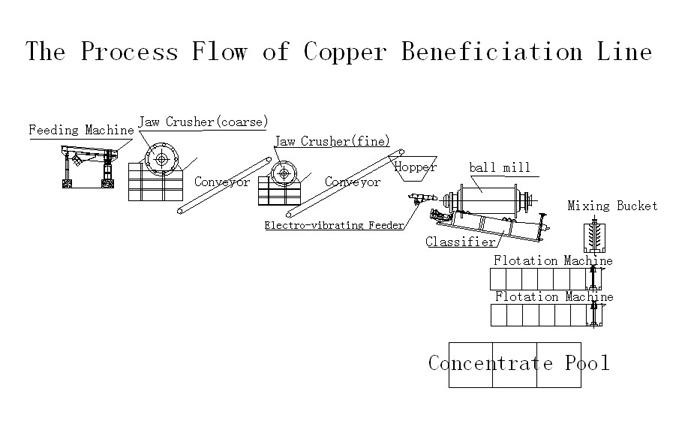

Working process of flotation plant

The whole flotation plant consists of jaw crusher, ball mill, spiral classifier, stirring tank, flotation machine, concentrator and dryer, etc. Mineral separation plant is high-efficient and energy-conserving.

Flotation separation process

1. Mined ores are firstly crushed by jaw crusher and then evenly delivered into ball mill for grinding through elevator and feeder.

2. The ground minerals are classified by spiral classifier.

3. The just-separated fines are primarily condensed by concentrator, and then dried by dryer, since they contain a lot of water.

According to your demands, we can design the most efficient and economical flotation line for you for free. You can get the price, by messaging us on website, emailing us or consulting with our 24-hour on-line staff. Hope to hear your inquiry.

Send Enquiry

Please enter your requirement and contact information and we'll get back to you as soon as possible.

![]() 30 seconds for connecting online customer service

30 seconds for connecting online customer service

![]() within 24 hours for getting email reply

within 24 hours for getting email reply

![]() factory-direct sale, 100% factory price

factory-direct sale, 100% factory price