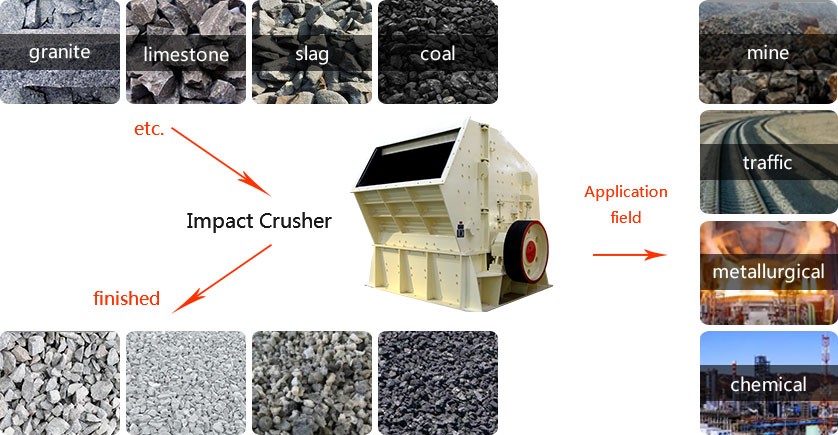

Impact Crusher

Processing capacity: 30-800t/h

Feed opening: 400×730-1260×2040mm

Feeding size: 300-700mm

Applied material: limestone, granite, coal, slag, clay. Get price list

you can click the button and contact us.

An Overview of Impact Crusher

Impact crusher consists of a feed hopper, feeder, swirling crushing chamber, an impeller body, a main shaft assembly, a transmission device, and a motor, totally seven parts. It has the advantages of simple structure, low cost, stable operation, high efficiency and energy saving.

Due to materials' dramatically lining in impeller and eddy broken cavity, the cost of wear parts and repair workload are reduced, which effectively solves the "iron pollution" problem of the broken glass and other raw materials in the process of crushing and "steel blocked" issue in the process of breaking steel slag. The clever internal air circulation eliminates the dust dispersion.

Application of Impact Crusher

Impact crushers are suitable for materials whose compressive strength is under 360Mpa and side length is less than 500mm. They are preferred to crush granite, limestone, ravel gravel, etc.

We design and supply primary and secondary impact crushing plants. The impact crusher manufactured by our company is a highly popular plant for secondary crushing applications. It is an ideal crusher that handles concrete full of rebar, asphalt and other debris to produce highly salable materials. The impact crusher is designed with cubic shape and features convenient operation and maintenance, high efficiency and energy saving.

It can achieve selective crushing. Particularly in Particularly in processing the hard, extra hard and abrasive materials such as silicon carbide, corundum, sintered bauxite and magnetite, Hongxing impact crusher has more advantages than other types of crushing machines. For construction sand, gravel which is used in roads is especially appropriate.

Cutting Edge of Impact Crusher

Impact crusher is popular all over the world in recent 20 years. Impact crusher has been proved that this series of crushers can effectively increase productivity and final product quality. And they can also greatly reduce the investment costs and operation costs. Incomparable excellent performance is shown in the secondary crushing, tertiary crushing and material recovery.

1. Unique simple structure, keyless connection, easy maintenance

2. High-chromium plating hammer and special impact liner plate.

3. Capable of highly efficient hard rock crushing while saving energy.

4. The final product of impact crusher is in the shape of a cube; the discharge grain size is adjustable to simplify the crushing circuit.

5. Reliable performance.

Parameters Type

| Model | Specifications(mm) | Feed Openting(mm) | Maximum Feeding size(mm) | Capacity(t/h) | Power(KW) | Dimensions L×W×H(mm) |

| PF1007 | ø 1000×700 | 400×730 | 300 | 30-70 | 4P 37-45 | 2330×1660×2300 |

| PF1010 | ø 1000×1050 | 400×1080 | 350 | 50-90 | 4P 45-55 | 2370×1700×2390 |

| PF1210 | ø 1250×1050 | 400×1080 | 350 | 70-130 | 6P 110 | 2680×2160×2800 |

| PF1214 | ø 1250×1400 | 400×1430 | 350 | 80-180 | 6P 132 | 2650×2460×2800 |

| PF1315 | ø 1320×1500 | 860×1520 | 500 | 100-280 | 6P 200 | 3180×2720×3120 |

| PF1320 | ø 1320×2000 | 993×2000 | 500 | 140-380 | 6P 250 | 3220×3100×3120 |

| PF1520 | ø 1500×2000 | 830×2040 | 700 | 200-550 | 4P 315-400 | 3959×3564×3330 |

| PF1820 | ø 1800×2000 | 1260×2040 | 800 | 300-800 | 6P 630-710 | 4400×3866×4009 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Send Enquiry

Please enter your requirement and contact information and we'll get back to you as soon as possible.

![]() 30 seconds for connecting online customer service

30 seconds for connecting online customer service

![]() within 24 hours for getting email reply

within 24 hours for getting email reply

![]() factory-direct sale, 100% factory price

factory-direct sale, 100% factory price