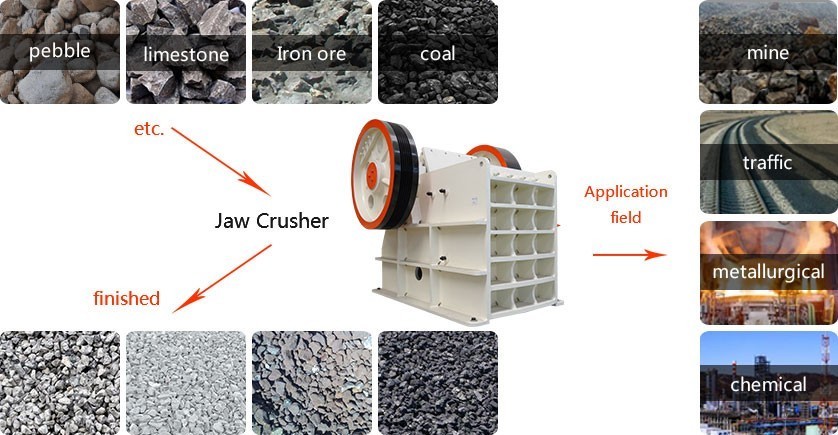

Jaw Crusher

Production capacity: 5–2200 t/h

Feeding size: 125–1200 mm

Material handling: pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, limestone, construction waste, etc Get price list

you can click the button and contact us.

Description of Jaw Crusher

Jaw crusher can be used together with gravel processing equipment as well as used independently. Hongxing small jaw crusher, PE jaw crusher and mini jaw crusher are used as Primary crushers and Secondary crushers for crushing all kinds of minerals and rocks with compressive strength less than 320 MPa.

There are two types of Jaw crushers: Coarse jaw crusher and Fine jaw crusher.

Hongxing Machinery also manufactures Mobile jaw crusher, small jaw crusher, PE jaw crusher and mini jaw crusher.

Small jaw crusher (mini jaw crusher)

Small jaw crusher or mini jaw crusher enjoys low price and small volume. Customers who just want to crush a little materials occasionally can choose PE jaw crusher which can greatly reduce the cost.

Small jaw crusher and large jaw crusher are different in size, but the working principle is the same, so customers can consult jaw crusher manufacturer for more details according to specific requirement when choose and buy jaw crusher.

mini jaw crusher

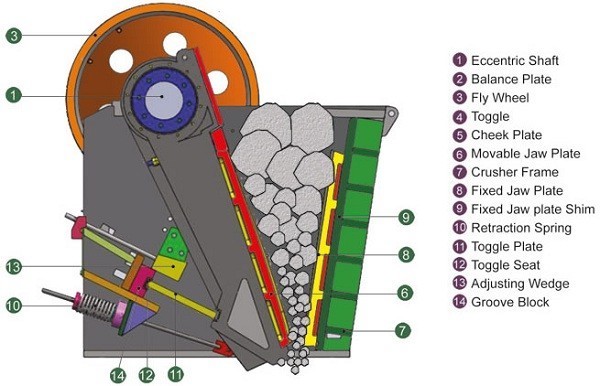

Working Principle of Jaw Crusher

The strip and strip pulley are driven by a motor, and the moving jaw moves up and down via eccentric shaft. The angle between fixed jaw and moving jaw becomes smaller when the moving jaw runs down, and then the materials are crushed into pieces.

The gap will become bigger when the moving jaw runs up. The moving jaw board leaves the fixed jaw board under the action of pole and spring, and then the end products come out from the crushing cavity. And also, jaw crusher is always used as the Primary jaw crusher.

mobile jaw crusher

Jaw Crushers Performance and Features

1. Crushing cavity is deep and without dead area, which improves feeding capacity and output;

2. High reduction ratio and uniform final product size;

3. Spacing piece type discharge-hole adjustment device is reliable and convenient;

4. Reliable and safe lubrication system, convenient replacement of parts and small work load of maintenance;

5. Simple structure, reliable operation and low cost;

6. Energy-saving, even single small jaw crusher, PE jaw crusher or mini jaw crusher can save energy by 15% to 30%; the system can save energy by over 30% to 60%;

7. Large adjustment range of discharge hole can meet the demands of different users;

8. Low noise and little dust;

9. Convenient maintenance and use, stable performance, low operation cost, high reduction ratio;

10. The outlet employs pad-style adjustment devices, convenient and reliable, and increases the flexibility of the equipment.

Hongxing Machinery is famous jaw crusher manufacturer and jaw crusher supplier in the world. welcome visit for cooperation. Leave us a message for more product details and price list?

Parameters Type

| Model | Feed opening size(mm) | Max.Feeding size (mm) | Adjustment range of discharge port (mm) | Capacity(t/h) | Rotation speed of eccentric shaft(r/min) | Power (kw) | Dimensions(L×W×H) (mm) |

| PE 150×250 | 150×250 | 125 | 10-40 | 1-3 | 268 | 4P 5.5 | 760×700×860 |

| PE 200×300 | 200×300 | 180 | 15-50 | 2-6 | 260 | 4P 7.5 | 915×780×990 |

| PE 200×350 | 200×350 | 180 | 18-60 | 3-10 | 276 | 4P 11 | 1000×914×1112 |

| PE 250×400 | 250×400 | 210 | 20-70 | 5-21 | 300 | 6P 15 | 1100×1032×1285 |

| PE 400×600 | 400×600 | 340 | 40-100 | 16-64 | 270 | 6P 30 | 1623×1736×1615 |

| PE 500×750 | 500×750 | 425 | 50-100 | 40-110 | 268 | 6P 55 | 1920×1850×1920 |

| PE 600×750 | 600×750 | 500 | 150-200 | 80-240 | 268 | 6P 55 | 2020×1850×1920 |

| PE 600×900 | 600×900 | 500 | 65-160 | 50-160 | 254 | 6P 55 | 2530×1900×2340 |

| PE 750×1060 | 750×1060 | 630 | 80-180 | 110-320 | 245 | 8P 110 | 2680×2380×2785 |

| PE 900×1200 | 900×1200 | 750 | 100-200 | 220-380 | 208 | 8P 110 | 3470×2876×3330 |

| PE1200×1500 | 1200×1500 | 1020 | 150-350 | 400-1000 | 180 | 8P 160-245 | 4850×3220×3680 |

| PE1500×1800 | 1500×1800 | 1200 | 220-350 | 500-1200 | 180 | 8P 280-380 | 5160×3660×4248 |

| PEX 150×750 | 150×750 | 120 | 18-48 | 8-25 | 320 | 4P 15 | 1170×1575×1030 |

| PEX 250×750 | 250×750 | 210 | 25-60 | 13-35 | 320 | 6P 22 | 1550×1730×1470 |

| PEX 250×1000 | 250×1000 | 210 | 25-60 | 16-52 | 330 | 6P 30 | 1580×2006×1390 |

| PEX 250×1200 | 250×1200 | 210 | 25-60 | 20-61 | 330 | 6P 37 | 1780×2214×1430 |

| PEX 300×1300 | 300×1300 | 250 | 20-90 | 16-105 | 300 | 6P 55 | 2210×2320×1723 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Send Enquiry

Please enter your requirement and contact information and we'll get back to you as soon as possible.

![]() 30 seconds for connecting online customer service

30 seconds for connecting online customer service

![]() within 24 hours for getting email reply

within 24 hours for getting email reply

![]() factory-direct sale, 100% factory price

factory-direct sale, 100% factory price