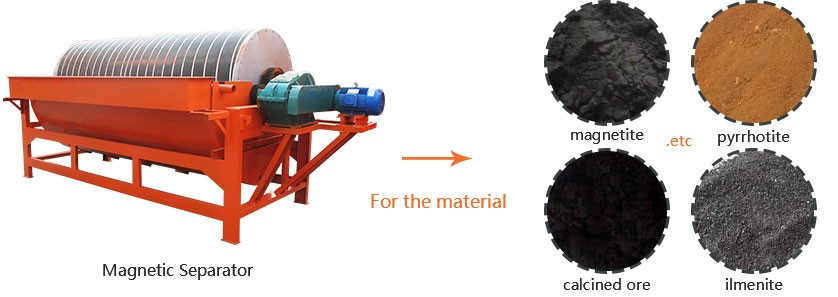

Magnetic Separator

Processing ability: 1–220 t/h

Feeding size: 0–3 mm

Shell diameter: 600–1500 mm

Applied material: magnetite, pyrrhotite, calcined ore, ilmenite, etc Get price list

you can click the button and contact us.

General Introduction to Magnetic Separator

Magnetic Separators are devices that are primarily used for eliminating tramp iron from ores and for removing contaminating materials that can damage equipment. There are mainly two kinds of magnetic separators produced by our factory. They are wet magnetic separator, magnetic drum separator and magnetic separator machine.

In concentration processes, the magnetic separator machine is commonly used for sorting various types of metals. Similarly, in case of weak magnetic minerals such as hematite, limonite and garnet, they can be separated from the non-magnetic substances by the use of high-intensity separators.

Key Characteristics of Magnetic Separators

Hongxing Magnetic Separator was designed through magnetic field simulation by computer, having enough magnetic field and big magnetic attraction area to attract Ferro scraps from the materials.

Compact structure, low noise, easy maintenance, stable magnetic field from the ferrite or rare earth magnets, energy saving without excitation system.

Workable in the harsh working environment for long time based on the specially sealed bearing seat and the belt with automatic corrective function. For very sharp ferromagnetic tramps, the unique belt armored by stainless steel plate is available to protect the belt from destroying.

There is common and explosion-proof drive motor for customer choice.

Because of using high power rare earth magnets, HX serial separators have high magnetic field gradient, stable magnetic field, super attraction that can remove big Ferro blocks and small Ferro scraps from the materials, even remove the ferromagnetic scraps buried in the thick material layers continuously.

Major Advantages of Permanent Magnetic Separators

Short magnetic circuit; little magnetic flux leakage; high magnetic intensity; Low energy consumption; fine beneficiating results; simple structure and easy maintenance.

Parameters Type

| Model | Shell diameter (mm) |

Shell lenght (mm) |

Shell rotation speed(r/min) |

Feeding size (mm) |

Processing capacoty (t/h) |

Power(kw) |

| CTB6012 | 600 | 1200 | <35 | 2-0 | 10-20 | 1.5 |

| CTB6018 | 600 | 1800 | <35 | 2-0 | 15-30 | 2.2 |

| CTB7518 | 750 | 1800 | <35 | 2-0 | 20-45 | 2.2 |

| CTB9018 | 900 | 1800 | <35 | 3-0 | 40-60 | 3 |

| CTB9021 | 900 | 2100 | <35 | 3-0 | 45-60 | 3 |

| CTB9024 | 900 | 2400 | <28 | 3-0 | 45-70 | 4 |

| CTB1018 | 1050 | 1800 | <20 | 3-0 | 50-75 | 5.5 |

| CTB1021 | 1050 | 2100 | <20 | 3-0 | 50-100 | 5.5 |

| CTB1024 | 1050 | 2400 | <20 | 3-0 | 60-120 | 5.5 |

| CTB1218 | 1200 | 1800 | <18 | 3-0 | 80-140 | 5.5 |

| CTB1224 | 1200 | 2400 | <18 | 3-0 | 85-180 | 7.5 |

| CTB1230 | 1200 | 3000 | <18 | 3-0 | 100-180 | 7.5 |

| CTB1530 | 1500 | 3000 | <14 | 3-0 | 170-280 | 11 |

Send Enquiry

Please enter your requirement and contact information and we'll get back to you as soon as possible.

![]() 30 seconds for connecting online customer service

30 seconds for connecting online customer service

![]() within 24 hours for getting email reply

within 24 hours for getting email reply

![]() factory-direct sale, 100% factory price

factory-direct sale, 100% factory price