Raymond Mill

Processing ability: 2-120 t/h

Feeding size: ≤15-≤30mm

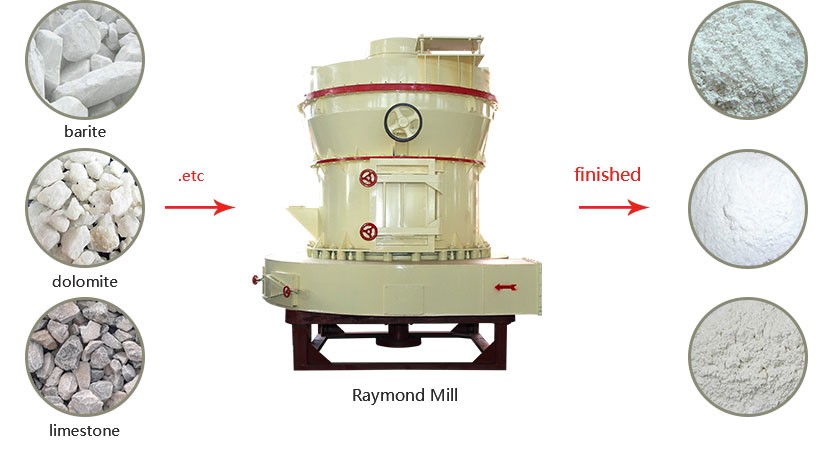

Applied material: barite, calcite, feldspar, talc, marble, limestone, dolomite, fluorite. Get price list

you can click the button and contact us.

Brief Introduction to Raymond Mill

Raymond mill is applicable to the grinding and processing of more than 280 kinds of non-flammable and non-explosive materials with hardness less than 7 and humidity less than 6% in mining, construction, chemical industry and metallurgy, such as stone flour, barite, bentonite, calcium carbonate, clinker, coal, dolomite, lead xide, limestone, marble, quartz, ultrafine.

Shipping of Hongxing Raymond mill

The fineness of the finished product can be adjusted from 100 meshes to 325 meshes according to requirements. Raymond mill is the main and widely used grinding machine.

Raw materials before being grinded and after being grinded

Workshop of Hongxing Raymond mill

After many years of practice and improvement, its structure is getting perfect day by day. Due to low consumption, low investment, environment friendliness, small occupation area and more efficiency than the traditional mill, Raymond grinding mill is widely used in the field of metallurgy, building materials, chemical industry and mining to process powder.

Structure of Raymond Mill

1. The whole grinding plant is a vertical structure of systematic characteristic, so it occupies small area. It is an independent production system from crushing of raw material to grinding and packing.

2. Compared with other grinding plants, its passing ratio achieves 99%, which is what other mills cannot reach.

3. Driving system of main frame adopts airtight gearing and pulley, drives smoothly and operates reliably.

4. Main parts of the Raymond grinding mill are made from cast and steel of high quality. The techniques are so subtle that they insure the durability of the whole plant.

5. The electric control system is integratedly controlled, so the automaticity is high. No people are needed in the operating room.

Supporting hopper of Hongxing Raymond mill

Supporting equipment---blower

Maintenance and Repair of Grinding Plant

1. Operators of the grinding plant have to be technically trained to know the principle and rules of operation. Someone should be specially selected and put in charge of the operation.

2. To ensure normal operation of the Raymond mill, a manual containing strict rules and procedures for its operation, maintenance and repair should be well prepared and followed. Tools, replacement parts for maintaining, repairing and lubricating oil and grease must be available for immediate use.

Installation site of Hongxing Raymond mill

3. After a period of usage, the Raymond grinding mill should be checked, to replace worn-and-torn parts such as rollers, rings and shovels. Be sure to fasten connecting-bolts, nut collars to fix rollers properly. Be sure to lubricate the parts sufficiently.

4. Roller should be replaced after 500-hours use. Raymond mill is to check and wash bearings in them and replace broken ones, and then fills enough oil and grease (with oil-pump or grease-gun).

Parameters Type

| Parameter Model |

Raymond mill62 | High strength66 | High strength76 | High strength87 | High strength92 | High strength93 | High strength97 | Raymond mill4119 | Raymond mill4525 |

| Feeding size(mm) |

<15 | <15 | <20 | <25 | <25 | <25 | <25 | ≤25 | ≤30 |

| Size of finished product(mm) |

0.173-0.033 | 0.173-0.033 | 0.173-0.033 | 0.173-0.033 | 0.173-0.033 | 0.173-0.033 | 0.173-0.033 | 0.173-0.044 | 0.173-0.044 |

| Shift output of different material fineness(t) |

0.6-9 | 1-20 | 1.5-25 | 2.8-33 | 3-36 | 3.5-40 | 4-52 | 8-78 | 16-176 |

| Rotate speed of central shart(r/min) |

274 | 190 | 170 | 161 | 148 | 140 | 130 | 105 | 82 |

| Diameter of pulverizing ring(mm) |

525 | 725 | 850 | 907.5 | 973 | 1006 | 1050 | 1400 | 1770 |

| Diameter of pulverizing ring(mm) |

150 | 210 | 250 | 270 | 300 | 300 | 310 | 410 | 450 |

| Height of pulverizing roller(mm) |

100 | 150 | 150 | 150 | 160 | 160 | 170 | 190 | 250 |

| Main Motor(kw) | 7.5 | 15 | 18.5 | 22 | 30 | 30 | 37 | 75 | 132 |

| Fan Motor | 4-5.5 | 4-11 | 4-15 | 4-18.5 | 4-22 | 2-22 | 4-37 | 4-75 | 4-132 |

| Analyzer Motor | 6-1.1 | 6-2.2 | 6-2.2 | 6-2.2 | 6-2.2 | 6-3 | 4A-5.5 | 4B-7.5 | 4A-18.5 |

Send Enquiry

Please enter your requirement and contact information and we'll get back to you as soon as possible.

![]() 30 seconds for connecting online customer service

30 seconds for connecting online customer service

![]() within 24 hours for getting email reply

within 24 hours for getting email reply

![]() factory-direct sale, 100% factory price

factory-direct sale, 100% factory price