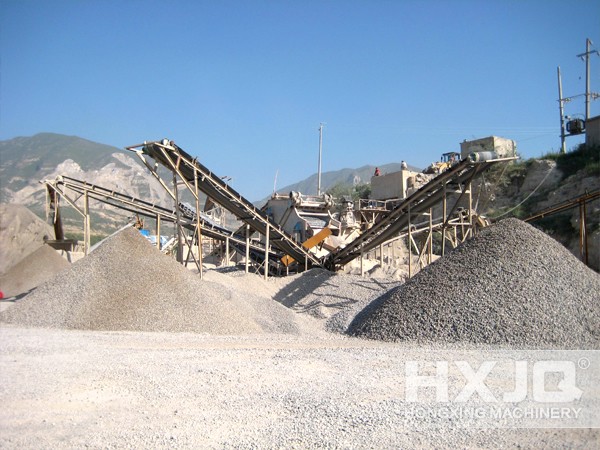

Sand making plant

Production capacity: 12-520t/h

Feeding size: 150-1,500mm

Discharging size:≤5mm

Processible materials: pebble, cobblestone, quartz sand, dolomite, basalt, etc. Get price list

you can click the button and contact us.

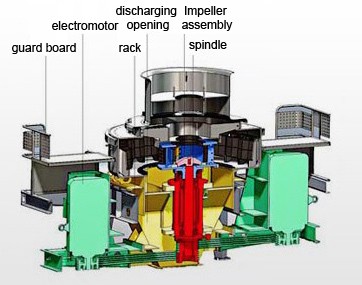

The whole sand making plant is composed of vibrating feeder, jaw crusher, sand maker, sand washer, vibrating screen and belt conveyor, etc. Sometimes, it can be equipped with impact crusher and hammer crusher. What's more, the sand production line can be customized.

Working process of sand making plant

Raw minerals in bin are evenly conveyed into jaw crusher for coarse crushing through vibrating feeder, then into PEX jaw crusher through belt conveyor for secondary crushing.

After that, crushed materials are screened by vibrating screen. For the crushed materials with size larger than feeding mouth of impact crusher, they are delivered to PEX jaw crusher again for tertiary crushing. For those qualified crushed materials, they are fed into sand washer for cleaning. The cleaned products are finally conveyed to piles via conveyor.

Advantages of sand making plant:

Flexible equipping: You can change the crushing devices according to different situations. If you want to produce much finer sands, the last crushing process can be replaced by sand maker.

Dedusting device is installed in, which can avoid the dust pollution.

High automatic degree: Except the daily maintenance and turn-on or off, human care is not needed.

Finished products are clean, cubic shape and even size.

According to the desiring output and raw materials, machines used to equip the sand making plant or sand production plant are different. Except for the most reasonable and economic sand production line, we can also offer you the before-sale service, sales service and after-sale service. If you are interested in our sand making plant, welcome you to leave message for us or email us.

Send Enquiry

Please enter your requirement and contact information and we'll get back to you as soon as possible.

![]() 30 seconds for connecting online customer service

30 seconds for connecting online customer service

![]() within 24 hours for getting email reply

within 24 hours for getting email reply

![]() factory-direct sale, 100% factory price

factory-direct sale, 100% factory price