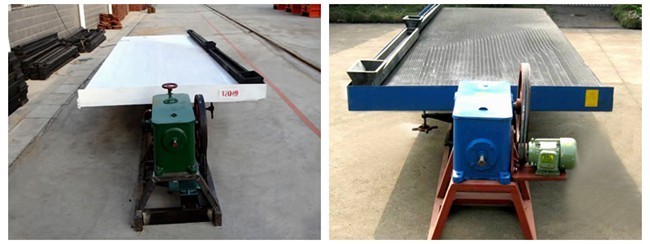

Shaking Table

Processing ability: 10–60 t/h

Feeding size: 0.15–2 mm

Feeding thickness: 15–30%

Applied material: tin, tungsten, gold, silver, lead, zinc, tantalum, niobium, titanium, manganese, iron ore, coal, etc Get price list

you can click the button and contact us.

Introduction to Shaking Table

Shaking table or gold shaker table is a mine selecting machine for fine materials working by gravity. Shaking table is widely used in selection of tin, tungsten, gold, silver, lead, zinc, tantalum, niobium, iron, manganese, ferrotitanium and coal. Our company has long history in producing shaking table separation; we provide varieties of gold shaker tables with high processing capacity, high recovery rate and high enrichment ratio. Concentrator table price in our company is much more competitive than other corporation.Application of Gold Shaker Table

Concentrating Tables are designed to wet gravity-based separation of minerals and other granular materials. There are many applications where the concentrator table is of particular value and cannot be equaled for economical and efficient performance. They are effective in processing precious and base metal, rare metal and non-metallic minerals.The Benefits of Shaking Table

Shaking Table features good high-grade ore sorting rate, high efficiency, and easy operation and maintenance, easy stroke adjustment. When we change the horizontal slope and stroke, the shaker can still maintain running balance.

Concentrator Table Price

Our company-----Henan Hongxing Mining Machinery Co., Ltd has long history in producing gold shaker table; we can provide varieties of table concentrators with reasonable price and high quality.

Shaking Table Separation

Shaking table separation, a gravity separation machine, is divided into hydraulic shaking table and wind shaking table. The current shaking table is generally driven by electromotor. The separation process of gold shaker table, which is mainly applied in the screening and separation of mineral grain, is conducted in the broad and oblique bed surface. The feeding size of shaking table which is suitable for the separation process of tin, tungsten, lead, iron, manganese and coal is usually under 3mm.

Parameters Type

| Name | Grit concentrator table |

Fine sand concentrator table |

Sludge concentrator table |

|

| Bed surface Dimensions |

Length (mm) |

4450 | 4450 | 4450 |

| Driving part Width (mm) |

1855 | 1855 | 1855 | |

| Concentrate part Width (mm) |

1546 | 1546 | 1546 | |

| Max.feeding size(mm) |

2 | 0.5 | 0.15 | |

| Feeding amount (t/d) |

30-60 | 10-20 | 15-25 | |

| Feeding thickness (%) |

25-30 | 20-25 | 15-25 | |

| Stroke (mm) |

16-22 | 11-16 | 8-16 | |

| Frequency (f) |

45-48 | 48-53 | 50-57 | |

| Bed surface Water quantity (t/d) |

80-150 | 30-60 | 10-17 | |

| Bed surface Horizontal obliquity(°) |

2.5-4.5 | 1.5-3.5 | 1-2 | |

| Bed surface Portrait obliquity(%) |

1.4 | 0.92 | ---- | |

| Table board corner(°) |

32-42 | 40 | 42 | |

| Concentrating area(㎡) |

7.6 | 7.6 | 7.6 | |

| Bed surface Length ratio |

2.6 | 2.6 | 2.6 | |

| Shape of side-bed surface |

Rectangle | Zigzag | Triangle | |

| Motor power(kw) |

1.1 | 1.1 | 1.1 | |

| Transmission device |

Eccentricity Linkage | |||

Send Enquiry

Please enter your requirement and contact information and we'll get back to you as soon as possible.

![]() 30 seconds for connecting online customer service

30 seconds for connecting online customer service

![]() within 24 hours for getting email reply

within 24 hours for getting email reply

![]() factory-direct sale, 100% factory price

factory-direct sale, 100% factory price