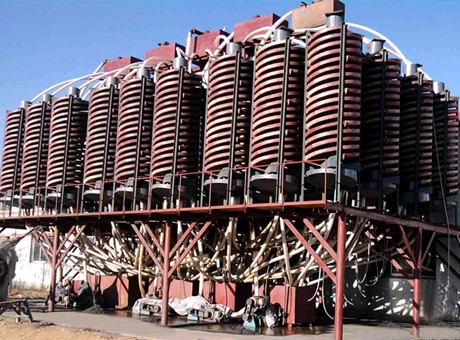

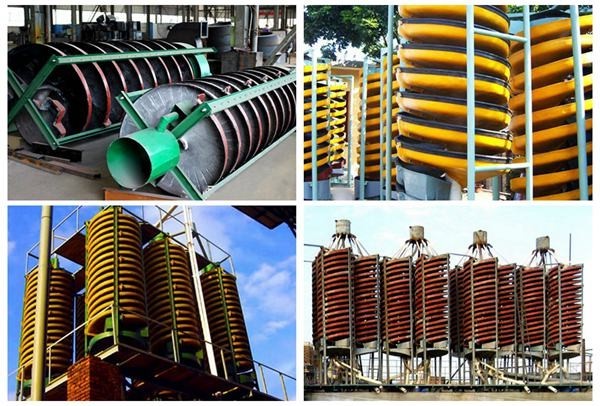

Spiral Separator

Production capacity: 0.15-6 t/h

Spiral diameter: 300-3000 mm

Material handling: iron ore, ilmenite, chromite, pyrite, zircon, rutile, monazite, tungsten, tin, tantalum, niobium, etc Get price list

you can click the button and contact us.

Introduction to Spiral Chute Separator

Spiral chute separator is the best equipment for mining and ore beneficiation especially for sand mining in the coast, riverside, sand bank and creek road. This product features reasonable structure, simple installation, small occupation area, simple operation, stable operation, large processing capacity, high recycle rate and reliable operation. In addition, it also features light weight, damp proofing, rust protection, corrosion protection and no noise.

Structure of Spiral Chute Separator

Spiral chute separator or spiral separator is composed of feeding ore homogenizer, tripod, feed chute, spiral flute, interception tank, concentration bucket and tank support.

Utilization Method and Working Principle of Spiral Separator

Because the spiral chute is working by taking advantages of gravity, it is also called gravity spiral chute or gravity chute.

The gravity spiral chute or gravity chute stands to adjust vertical line, and then the spiral chute can be fixed in the proper position by brandreth or wood. The mineral sand is sent to the two feeding ports by sand pump, and then the water is added to adjust the density of ore oar. A centrifugal force is produced at the flow rate of spiral slope due to the fact that ore oar flows from the high place. The mineral and sand are separated through the gravity and centrifugal force caused by spiral flow. The concentrate flows out from the pipeline to the spiral separator and the tailings are sent to the sand pool. Finally, the ore beneficiation is finished.

Send Enquiry

Please enter your requirement and contact information and we'll get back to you as soon as possible.

![]() 30 seconds for connecting online customer service

30 seconds for connecting online customer service

![]() within 24 hours for getting email reply

within 24 hours for getting email reply

![]() factory-direct sale, 100% factory price

factory-direct sale, 100% factory price