Hot Products

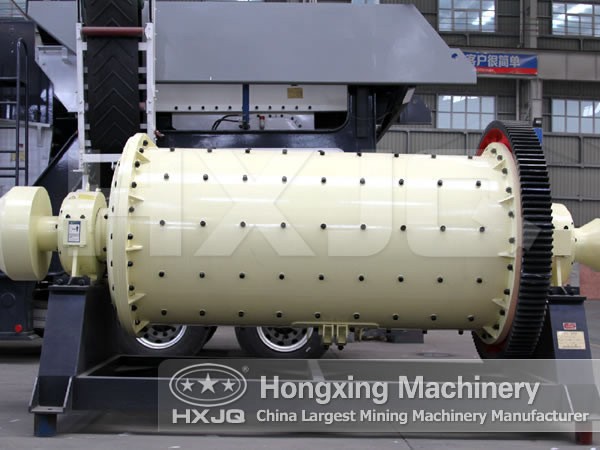

Selection Considertions of the Working Speed of Ball Mill

E-mail: market@hxjq.comThe selection of the working speed of ball mill is very important since it influences the production efficiency of ball mill. Here HXJQ will explain the conditions should be taken into consideration in the selection of the working speed of ball mill:

(1) The surface shape of scale board:

The surface shape with convex edge can reduce the relative sliding of crushing media. For this reason, if the workers increase the hoisting height, the working speed of the ball mill should be lower than that using smooth scale board.

(2) Mineral hardness and grinding fineness:

When roughly grinding the hard and large pieces of rock, you should use larger crushing media and higher working speed, which will be helpful to increase the impacting effect on the materials. On the contrary, you'd better use smaller crushing media and lower working speed in order to strengthen the crushing and grinding effects and reduce energy consumption.

(3) Grinding methods:

As for wet type grinding, due to the lubricating effect of water, there will be obvious relative sliding between the crushing media and the scale board. Therefore, on the similar condition, the working speed of wet ball mill should be improved by 5% higher than that of dry type ball mill.

(4) Filling ratio of crushing media:

The lower the filling ratio is, the higher the relative sliding will be. For this reason, the working speed should be higher. Through abundant experiment and rich experienced information, it was believed that improving the working speed of ball mill is beneficial from the perspective of output. The domestic experiential data shows that when the working speed is increased, the productivity can be greatly improved. But the life of scale board will be rapidly decreased and the power consumption will increase. Consequently, the working speed of the ball mill is often adjusted between 76% and 88%.